Link to the articles about Bamboo Pod 3:

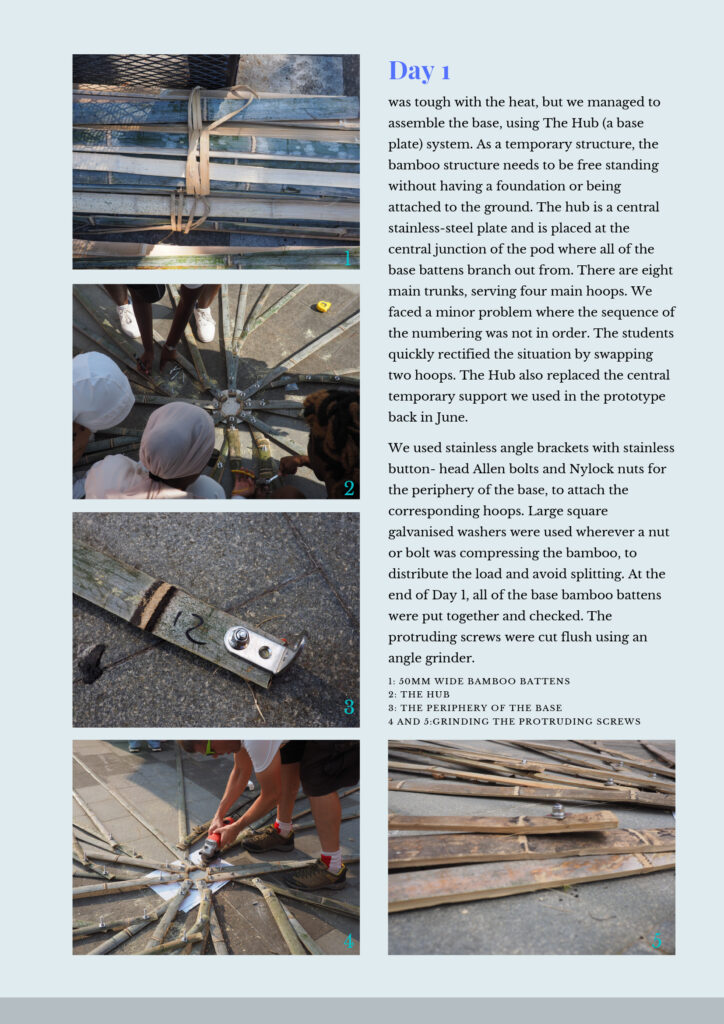

Day 1-5 YouTube link, please see below.

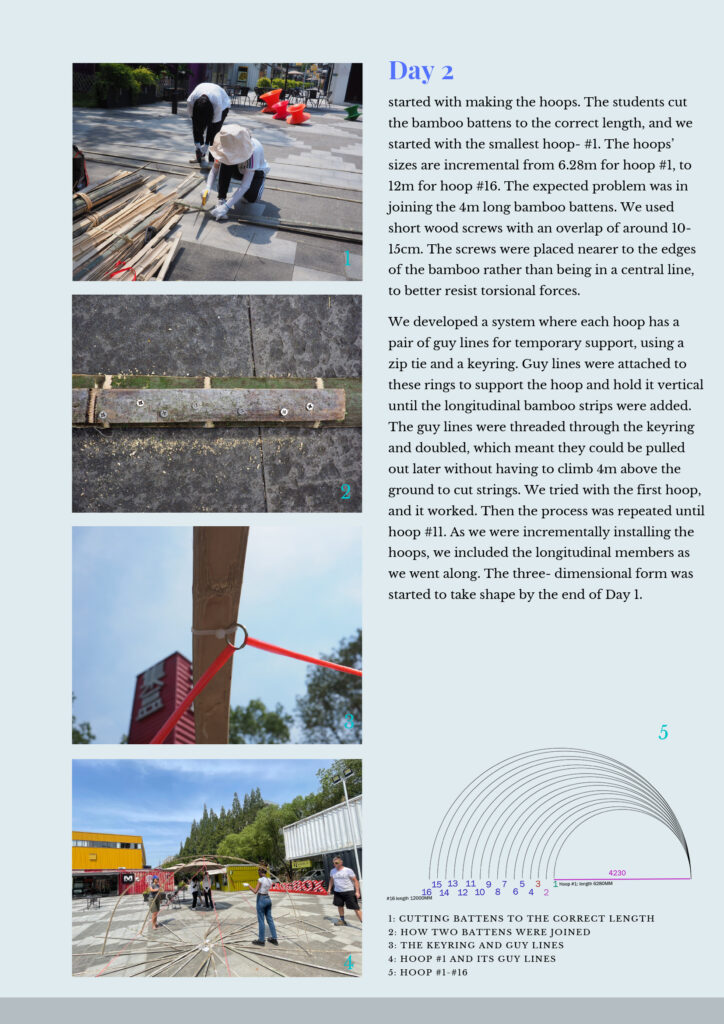

Day 1-5 YouTube link, please see below.

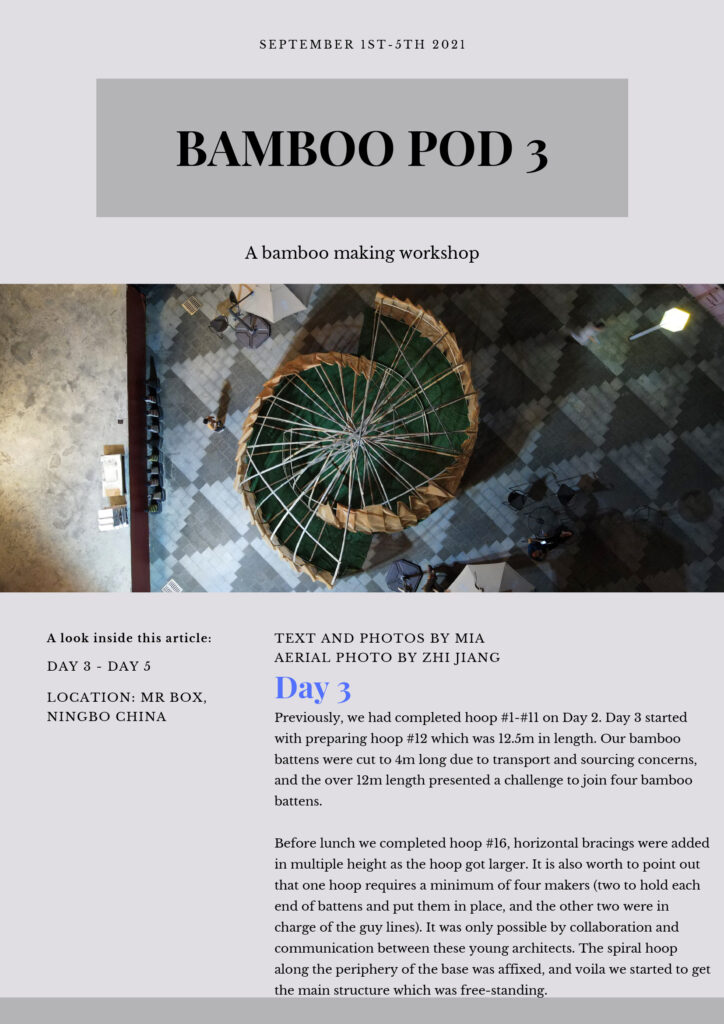

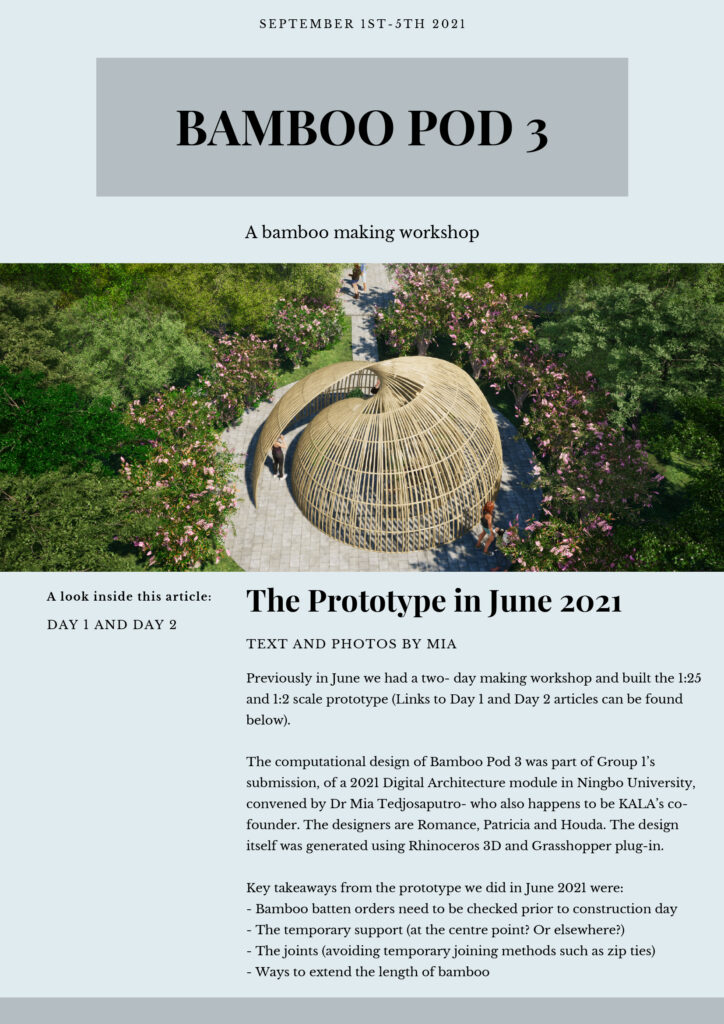

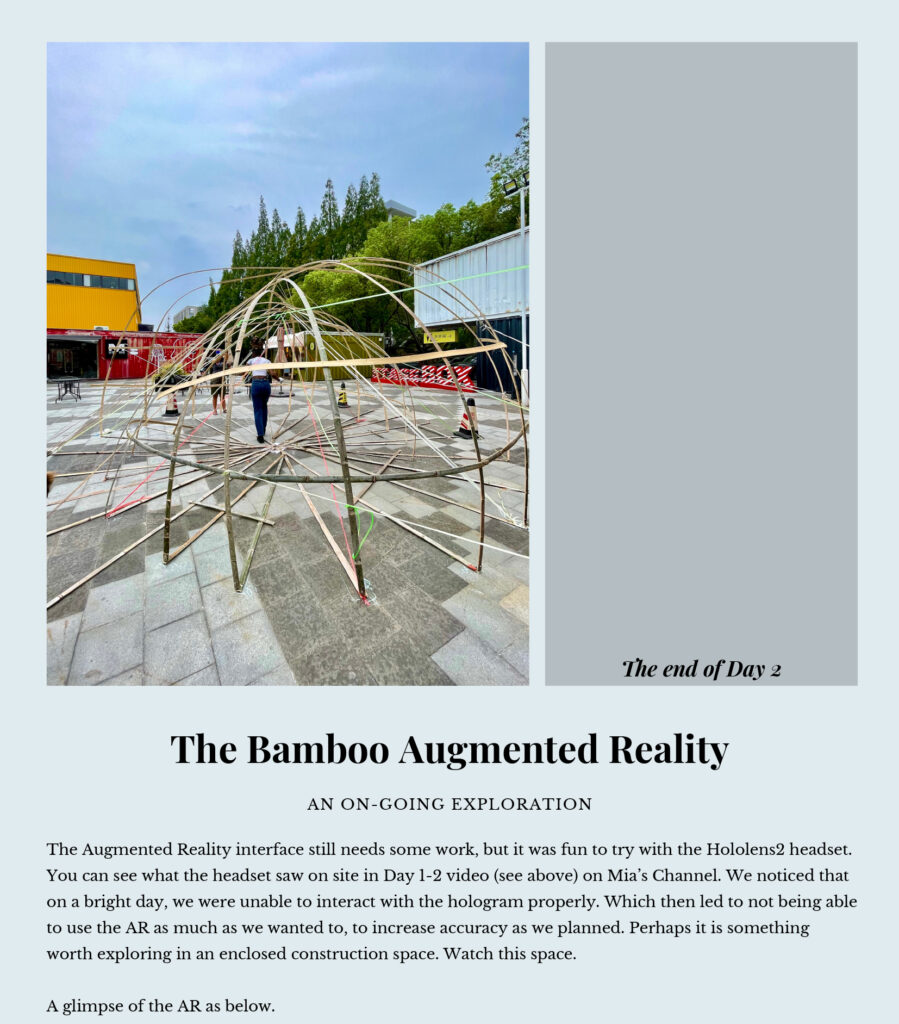

Day 2: Bamboo Pod 3 Prototype build at Mr Box, Ningbo.

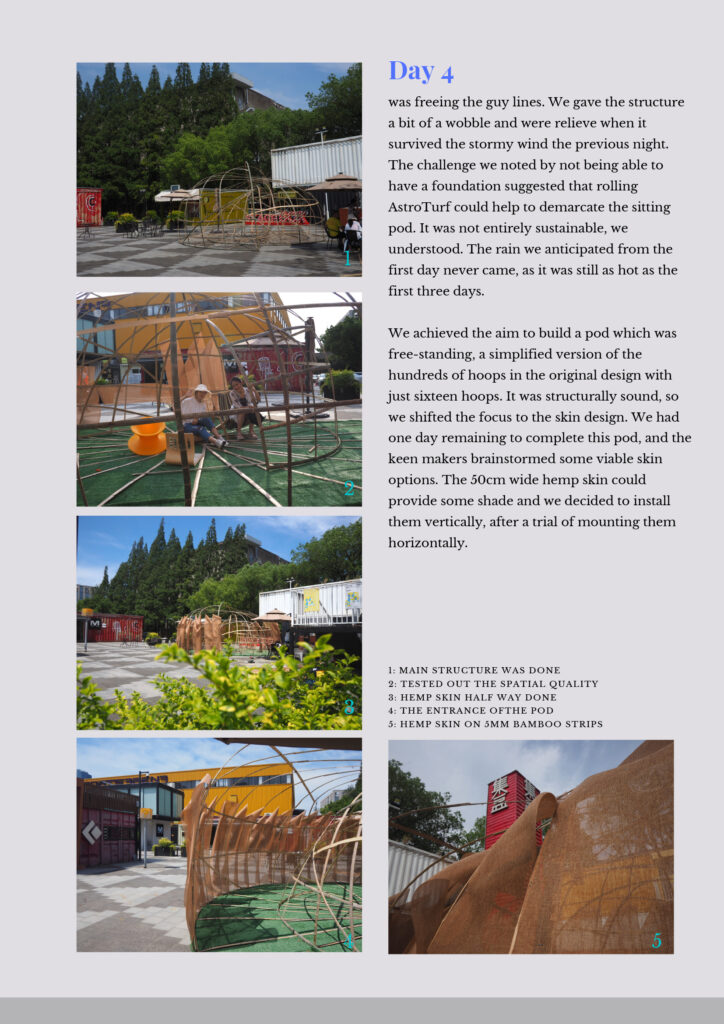

30 June 2021

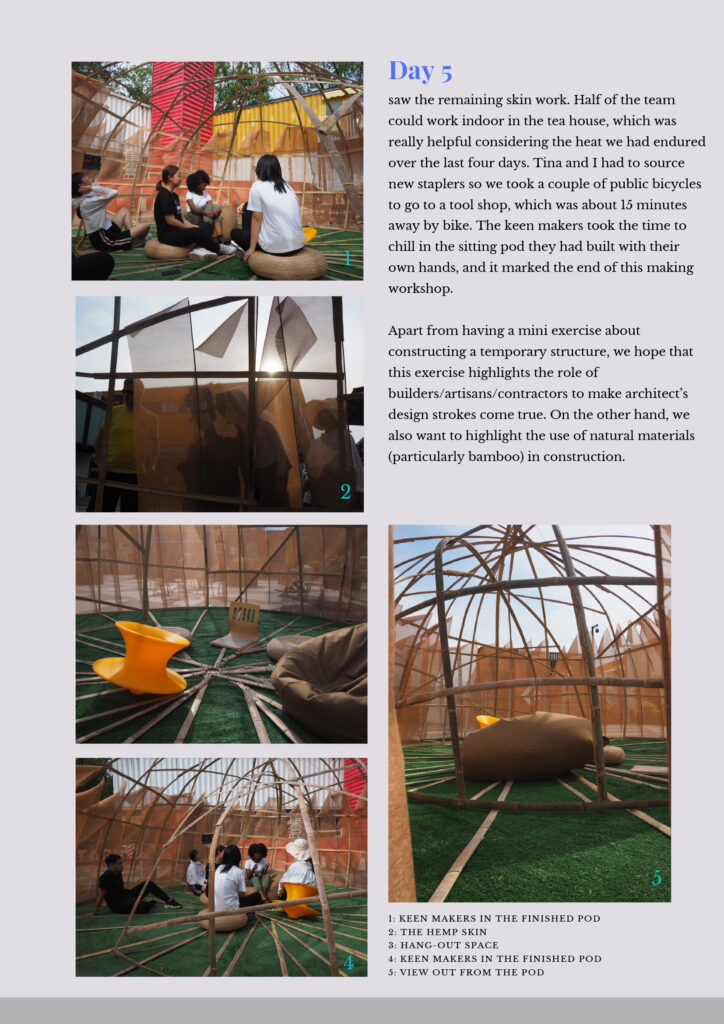

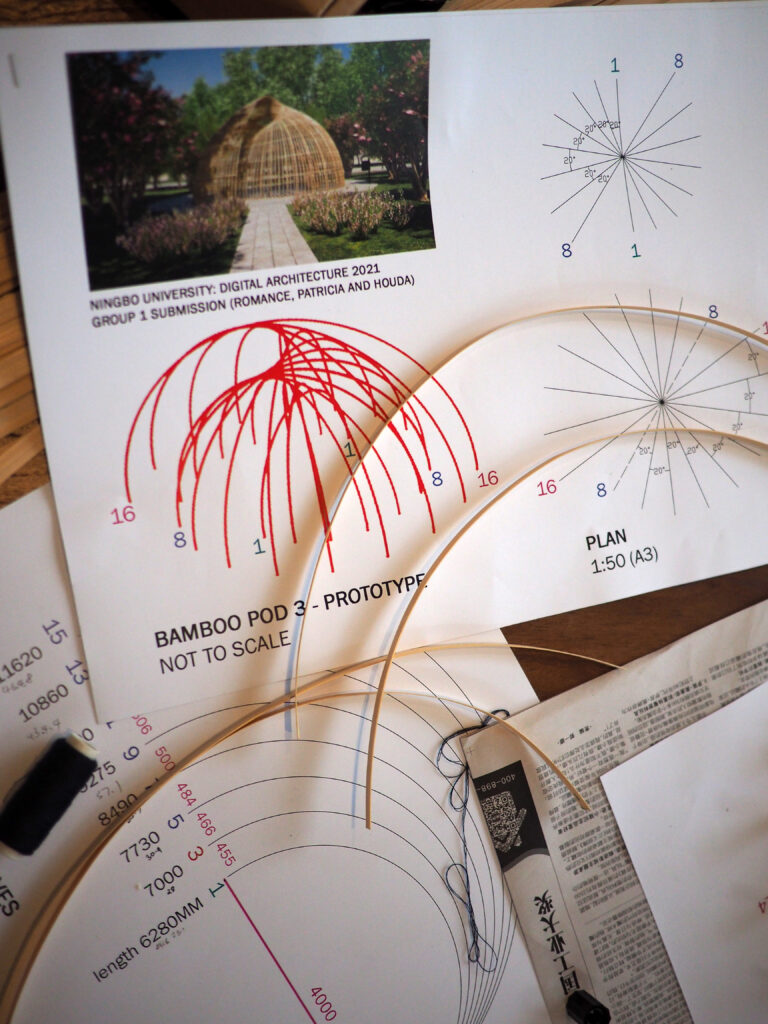

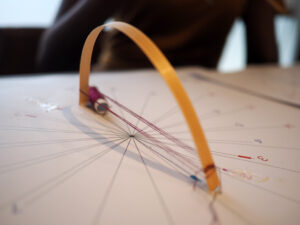

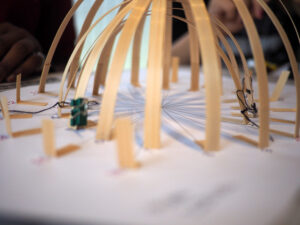

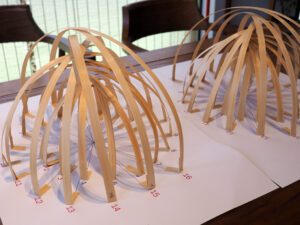

Day 1 (click here) started with retrieving the 16 mini sized arcs (with the wrong sized bamboo battens which were sent from the mountains yesterday- what a palaver). We are working on a 1:2 scale bamboo model. We noticed some off shaped ones so we re-measured them all. Plan had to change slightly accommodating the wrong size of bamboo battens as the hoops are mostly floppy!

We put up the temporary support: The centre column and three guy lines. We considered putting the 1:2 structure in between the existing planters so we can guy them up with additional guy on the concrete grill. This particular exercise is useful for the real size build, most definitely we will also need a temporary structure.

The bigger the diameter of the hoops, these non supported ones (from about #13 onwards) got really floppy and tended to twist. The team decided to proceed and added horizontal supports once all 16 hoops were in place.

The first layer of horizontal supports were up, then we continued with the next layers. In total we had 5 layers and the more we put the horizontal elements, the more stable the structure was. We removed the guy lines before adding the 5th layer, which was not planned. The joy of physical model making!

Then it was the acid test whether the structure will be self-supporting despite the wrong dimensions. We also learnt that probably 50mm would have been too wide for 1:2 scale, so not all mistakes went unreflected on. 20-25mm wide would have been a better size as the main structural system for this play tent for kids 🙂

Generally Matt and I are really happy with these two days. It was planned for three days, but some of the students had emergencies so we decided to start on Tuesday instead. The light rain on Tuesday morning presented a challenge, especially for Nancy whose flowing summer dress got wet every time she crouched down- which was a lot- but at least it kept things cool. It got quite hot in the afternoon. I enjoyed the experience as well, and knowing this project does not stop here gives me something to look forward too as a lecturer.

A few things we want to address for the final build are: the joints (zip ties are amazing for this kind of purpose but we rely too much on them: a more sustainable option such as hemp could be the better option), the floor ideally needs to have a base, and the possibility to be flat packed with stretchy horizontal joints so they can be a movable pod would all be good adjustments.

Our keen makers: Romance, Patricia, Francy, Serena, Nancy (Jianan Wang) and Joy (Qiaoyi Zeng)

Facilitators: Dr. Mia Tedjosaputro and Matt Wallwork

Thank you also goes to Neal (Fan Zeran), Wang Yin, Chenchu and Mr Box for making it possible.

Day 1: Bamboo Pod 3 Prototype build at Mr Box, Ningbo.

29 June 2021

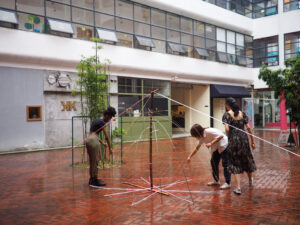

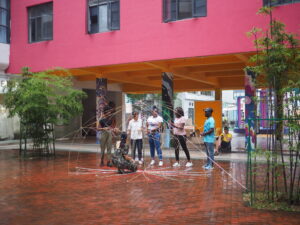

The day started with the participants arriving from various parts of the city to participate in this extracurricular, unofficial project. Nancy and Joy- two preliminary year architecture students from the University of Nottingham- travelled with Matt (Academic English teacher at University of Nottingham Ningbo China) and Mia (part time lecturer in both universities, Ningbo University and Nottingham) and we met up with Francy, Patricia, and Romance (Ningbo University architecture students, in year 4) at Xin Yi Yuan tea house. The first order of business was to collect the bamboo from the new camping shop at Black Box café, who had kindly stored it since it was delivered early that morning.

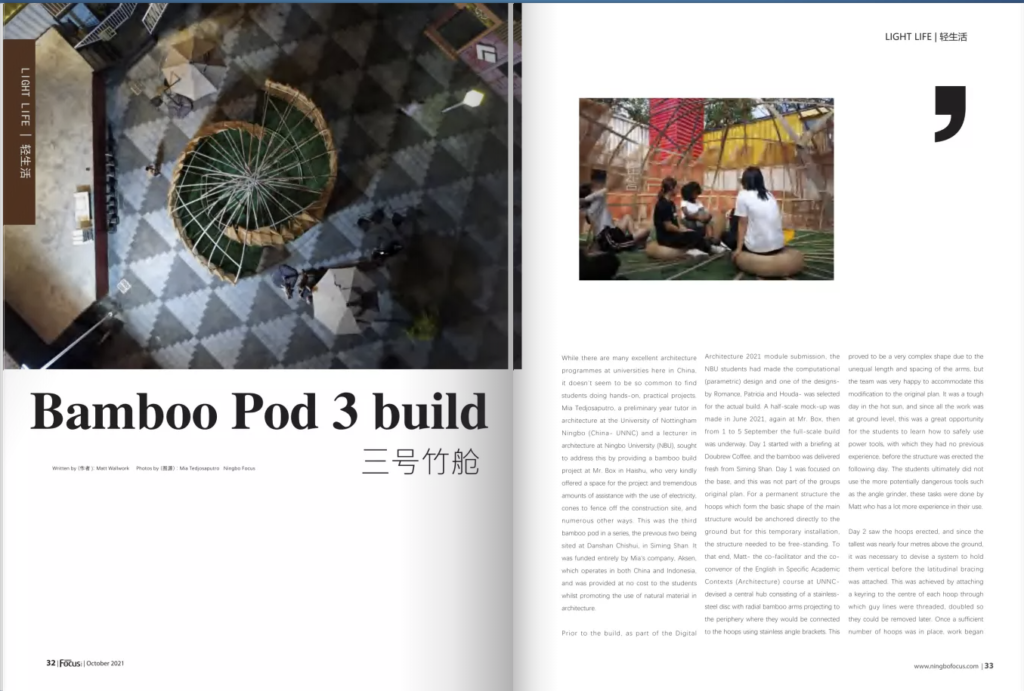

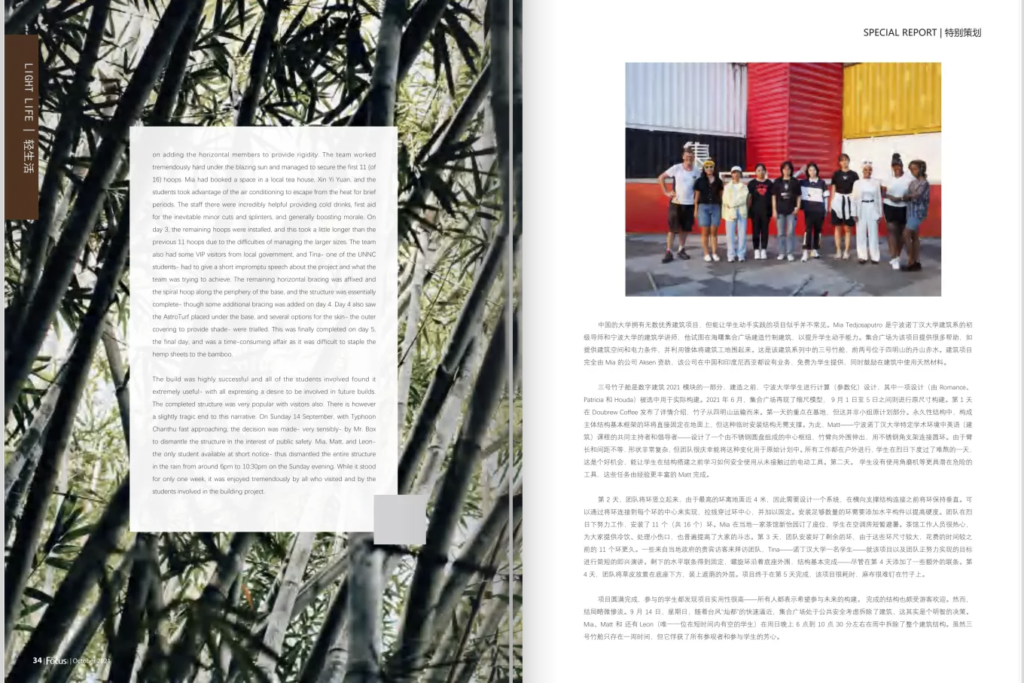

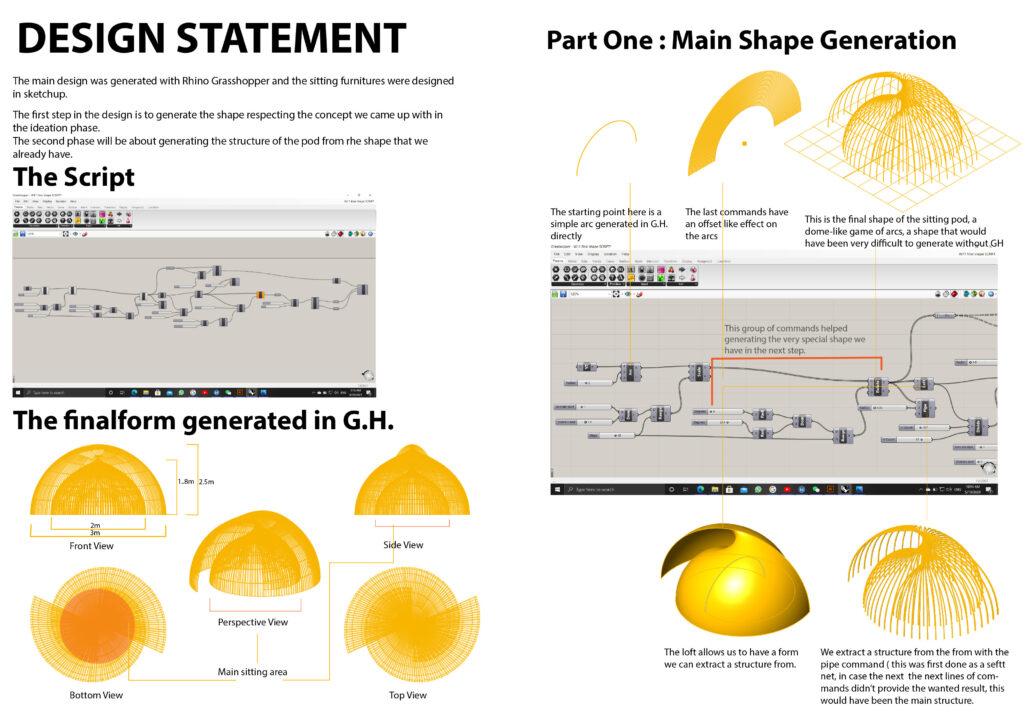

The bamboo pod design was part of Digital Architecture 2021 module in Ningbo University for Year 4 architecture students, it is developed and facilitated by Dr. Mia Tedjosaputro. The parametric design was generated by Group 1 as part of their Assignment 1 group submission, using Rhino 3D and Grasshopper. The team members are: Romance, Patricia and Houda. Due to the fact that most architecture students from NBU are still abroad due to the pandemic, only a handful number of students are in Ningbo and some of them joined this workshop.

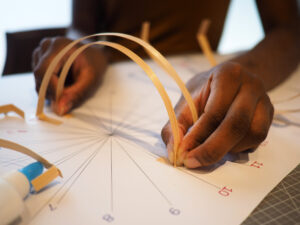

After brief introductions, including the café’s resident friendly cat, the 1:25 scale model making began. The students were spilt into two groups with a nice mix of Ningbo Uni and Nottingham students, so there was great collaboration between the two universities from the outset.

The students worked well to overcome the minor problems that inevitably appear during any construction project and overall this was a very valuable learning experience. This whole exercise is a prelude to a full-scale build of the structure in September. We only explore the main structural system which comprises of 16 hoops, testing out before we build the full scale of bamboo structure.

After lunch we started to build the 1:2 scale prototype. We had to deal with what appear to be a quite disastrous material sourcing. The 60 pieces of bamboo battens we requested was 50mm, and what came was 5mm wide. Structural system is affected, but we have to adapt and improvise. Quite a number of tools and materials are no longer necessary as they were prepared for the correct width.

Mr Box was incredibly accommodating for this project. Ningbo city itself is a great hive of creativity, and academic and artistic projects are really encouraged here. It is truly gratifying to be able to arrange a space for a project of this scale so easily, and to be so well supported throughout the whole project. It is immeasurably valuable for students to be able to have this kind of hands-on building experience, and for artists to have space to express themselves in a space where they will get public exposure, so the general public of Ningbo can also benefit. Here are a glimpse of Mr Box area:

Our heartfelt gratitude goes out to Mr Box, and to the Black Box café and Xin Yi Xuan tea house for being so flexible and making this whole rich experience possible. It was particularly valued by the Ningbo University students, as morale is a bit low at the moment- many of their cohort are in their home countries, unable to return to China due to Covid restrictions, and those who are here- the ones who have called Ningbo their home for the past four years- are few in number and studying online. This hands-on, face to face, practical extracurricular project was especially precious to them, so again- many thanks to Mr Box for facilitating this!

On another note, we had a couple of major catastrophes with materials, which goes a long way towards our future planning. Quite an intriguing exercise on prototyping stage, as there is no pressure to get the pod 100% up and perfect. Mistakes are expected, shall we say. Especially with a more manageable scale, 1:2. Day 2 tomorrow, bring it on!

Our keen makers: Romance, Patricia, Francy, Serena, Nancy (Jianan Wang) and Joy (Qiaoyi Zeng)

Facilitators: Dr. Mia Tedjosaputro and Matt Wallwork

Thank you also goes to Neal (Fan Zeran), Wang Yin, Chenchu and Mr Box for making it possible.

S24O (bike and camp) mini adventure!

Matt and I are blessed to be living not far from the great outdoors of Ningbo. When regular couples will book the most romantic dinner in favourite places on Valentine’s Day, we wanted to avoid the crowd. We indulge ourselves by going camping quite often in different seasons- in particular, to places which can be reached by bikes. So here is the time when we left our expensive road bikes at home and took the touring bikes instead.

Biking and camping are not a novel outdoorsy combination. This article illustrates how taking inspiration from nature has a great impact on how the KALA brand is shaped and is being developed. My great interest in natural materials as KALA’s design direction was a result of this too. The trip itself did not cost much as we cycled all the way there and carried our own gear and water.

Both Matt and I are not natural living zealots (nowhere near- we still carry plastic wrappers during our camping trips, for instance the crisps or baguette bag) but we also try to take small steps to reduce our less ideal consumption behaviour.

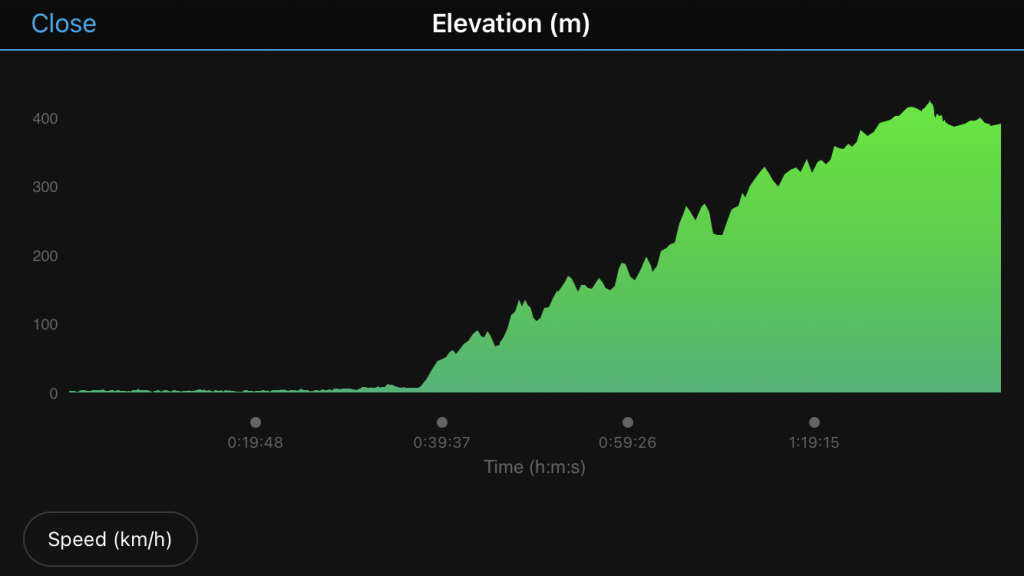

So we set off on Valentine’s Day (which was also our wedding anniversary) with two bikes. Matt carried most of the gear as usual (sleeping system and cooking gear) and I carried the tent and my camera in a special camera bag for bikes. The journey itself it was quite short, a mere 21km away with a 430+ metre climb. It turned to be a beautiful afternoon once we were done getting rained on. D’oh!

We got to the campsite at 5pm, just enough time to set the tent up before it got dark. There is no road light (nor any light) around the campsite. We found the site a few years back, during one of those adventurous and ‘see where this road takes us to’ kind of moments, but it didn’t link to any other roads.

KALA’s own insulated cup made for good company, it keeps our hot beverage (necessary when it got cooler once the sun set) warmer for longer. Tip: You can find this product in KALA’s Weidian online shop.

Like most camping people, we like the idea of camp cooking. We did not have the luxury of a campfire however. To save taking a small chopping board and the whole onion on the bikes, I pre-chopped one and put it in the re-usable beeswax wrapper. It was one of KALA’s products too (will be back with the coolest batik patterns KALA designed). I reused a bread tie I have been collecting every time we buy bread. Completely zero waste, I get to wash the wrapper and re-use the bread tie again. Valentine’s day’s main menu was beef with creamy corn soup, with a baguette to share for dipping. Just humble comfort food.

The sky was so clear that night and we got to see stars. We retired early (8pm) after sharing a bottle of wine we picked up in the nearest town (Hengxi) and the night was windier than we thought.

Mornings at the campsite are the ones to look forward to. Although the view was not as spectacular as the day before (a bit foggy), the tea plantations and the mountains still looked as majestic as they always are.

KALA’s bamboo drip coffee filter was in service, brewing a slow coffee. We did not take the stand for convenience, but the insulated cup was a good size (tall enough) making sure the filter is not merged in the coffee (which can result in clogging). Because the bamboo filter is light, it was perfect for this kind of mission.

I hope this short journey gives you inspiration for local adventures which are eco-friendlier, fun and memorable.

Products used on this trip which you can purchase from us are:

You can also view this article in our official WeChat account:

For English : https://mp.weixin.qq.com/s/lueQxP31YUefeWGmU_eLaw

For Chinese : https://mp.weixin.qq.com/s/n_EHnlE4Y-Uj6DeZeCU2Gg

ABOUT KALA

KALA was founded by Mia and Elza Tedjosaputro, in May 2020. KALA provides high quality stylish home decor and accessories that highlight a few simple attainable changes towards an eco-friendly lifestyle. There is always an Indonesian touch ensuring we empower our craftsmen and promote Indonesian culture and craftsmanship. KALA’s specific design language is the use of natural materials and artisanal, with a sense of play of texture and product functionality. We are based in Indonesia and China.

Our second alternative of re-using discarded element!

Lucky (æŽç´èŠ¬) is KALA’s fourth collaborator we kick started in January 2021. Her pivotal part started in December 2020 in relation to the batik scarves, she made sure the edges are cut and trimmed properly. She is a Ningbo- based tailor and has been making clothes since the age of 17. That is nearly 50 years of experience she is sharing with us!

This collaboration looks at another discarded item and turn them into a functional yet relatable product for your cosy home. It has twofold aims: one is to facilitate your ideas from your own otherwise discarded fabric, and the other one is to provide a ready to be used tool/ utensil organiser curated by the KALA team.

About the “B-hoop†organiser.

B-hoop stands for “bamboo hoop organiserâ€, made of bamboo embroidery hoop (diameter 30cm). The hoop is made of bamboo, with the specific advantage of the ready to be exploited hanging system, by using the metal clamp. They function as organisers for your art & craft tools, your stationery and many more.

A couple of options for you:

You can also view this article in our official WeChat account:

For English : https://mp.weixin.qq.com/s/J_N5RouPhnErBYrz0-i_Mg

For Chinese (ä¸æ–‡) : https://mp.weixin.qq.com/s/7DOSM3TFdiPXMXlyliSTkA

ABOUT KALA

KALA was founded by Mia and Elza Tedjosaputro, in May 2020. KALA provides high quality stylish home decor and accessories that highlight a few simple attainable changes towards an eco-friendly lifestyle. There is always an Indonesian touch ensuring we empower our craftsmen and promote Indonesian culture and craftsmanship. KALA’s specific design language is the use of natural materials and artisanal, with a sense of play of texture and product functionality. We are based in Indonesia and China.

Bamboo kayak: from firewood to floating!

LOCATION

Danshan Chishui, Siming Mountains, Ningbo China

ABOUT THE PROJECT

This isn’t a step- by- step guide to building a bamboo kayak, as if anyone wants to build one, you can basically make it up as you go along- that’s what we did!

We had a couple of temporary bamboo structures to dismantle (click here for Bamboo Pod #1 and Bamboo Pod #2 coverage), which had been a design and build exercise for students. This left us with a lot of weathered bamboo to play with, so we decided to make a kayak.

Video: cleaning dismantled materials

When bamboo has been exposed to nearly a year of rain, snow, sun and wind, it becomes very hard but quite brittle. For the curves we needed for the kayak however, it was fine. There are numerous ways of making the joints- peg and dowel, hemp/ plant-based epoxy lugs, etc. but time was a factor for us and this was only a prototype, so we used plastic zip ties, insulation tape and steel fencing wire.

The skin, again for expedience, was cling film (aka Saran wrap). This is cheap, lightweight, and self-amalgamating to a degree so all we had to do was wrap the whole thing a few times, then cut a hole in the deck to get into the kayak. It was a quick and relatively easy process. We hung the frame between two trees and just span the whole frame to wrap it. We’d estimate the total amount of plastic in this build to be in the order of 100 grams or so, so it’s not ideal but not too extreme.

Video: wrapping the skin

FUTURE DEVELOPMENTS

A more sustainable build would be to use the joining methods outlined above and a natural covering- our version 2 will be skinned with hemp cloth, which is of course not even slightly waterproof, impregnated with epoxy for waterproofing. The native Americans would use birch bark, which we don’t have access to, and the Inuit would use animal skins (which we’re not convinced of the sustainability of in our context, since we have different constraints).

We’re not kayak specialists by any means, and we’ve never made one before, so naturally enough- mistakes were made and lessons were learned. With Matt’s 86kg+ (ahem!) weight, the freeboard was too low, about 40-50mm (this is the height from the waterline to the top of the deck, where water could slosh in). The next one will be taller and more voluminous. However, it was stable, tracked straight (despite the deck being a bit warped), and light to paddle.

Video: Milly had a try. Video courtesy of Ben

Big thanks to Cai-cai, Lucky and the Persimmon team whom always welcome and facilitate our crazy ideas. Persimmon in Danshan Chishui is our second home in China. We cycle/hike/camp often around this area, it is 60km away from the University of Nottingham Ningbo China where our China home is. Easily accessible on our bikes.

ABOUT KALA

KALA was founded by Mia and Elza Tedjosaputro, in May 2020. KALA provides high quality stylish home decor and accessories that highlight a few simple attainable changes towards an eco-friendly lifestyle. There is always an Indonesian touch ensuring we empower our craftsmen and promote Indonesian culture and craftsmanship. KALA’s specific design language is the use of natural materials and artisanal, with a sense of play of texture and product functionality. We are based in Indonesia and China.

A gif each day’s milestones as follows:

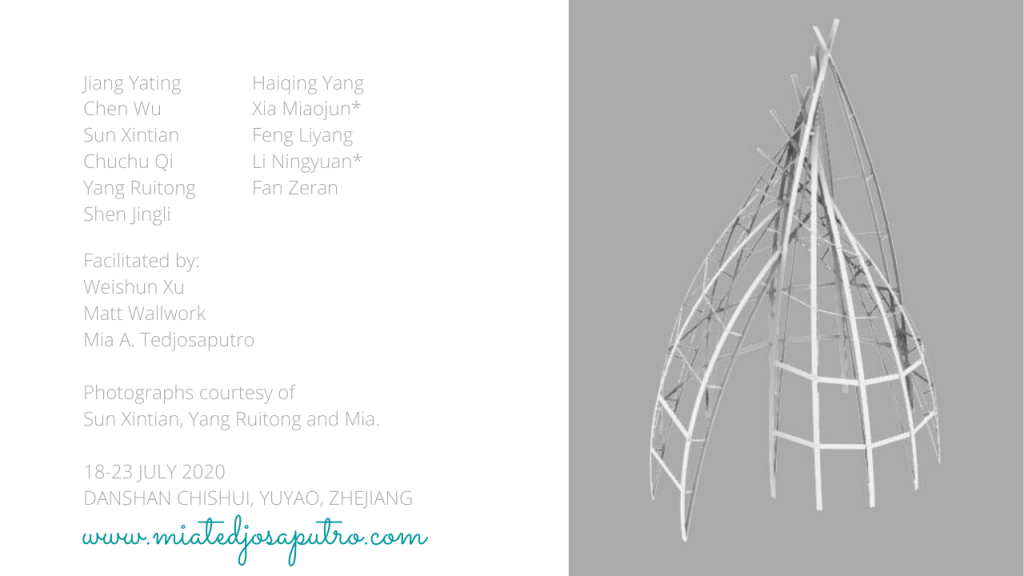

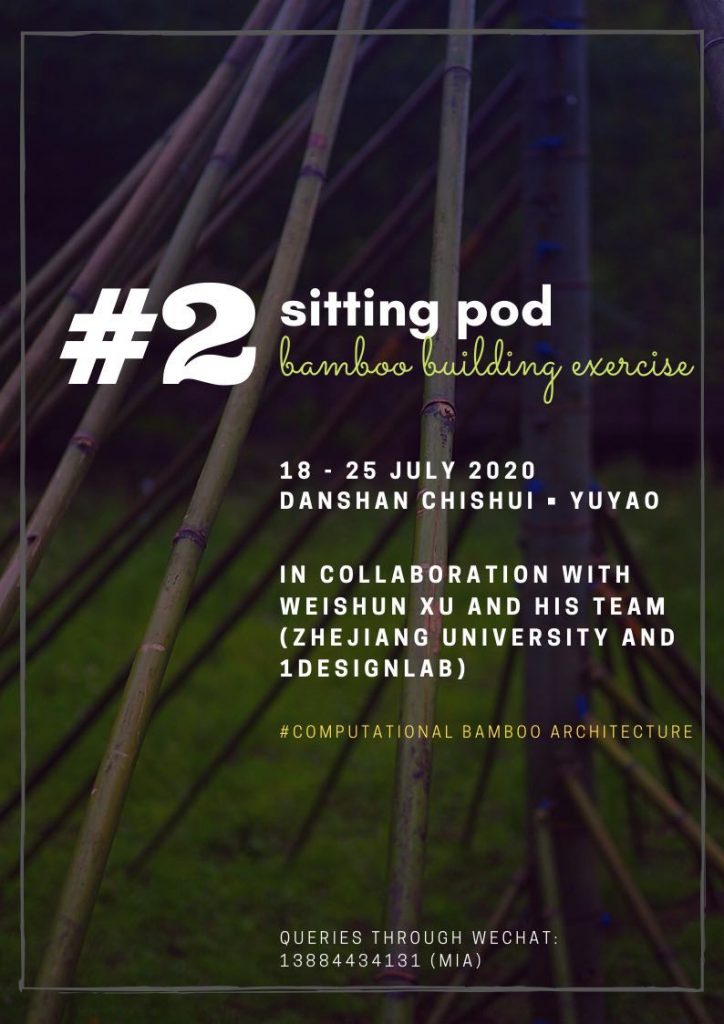

18-23 July 2020.

Danshan Chishui, Yuyao, Zhejiang, China.

Sponsored by Aksen (China and Indonesia), in collaboration with Weishun Xu from Zhejiang University.

Our keen designers and makers are:

Jiang Yating

Chen Wu

Sun Xintian

Chuchu Qi

Yang Ruitong

Shen Jingli

Haiqing Yang

Xia Miaojun*

Feng Liyang

Li Ningyuan*

Fan Zeran

Facilitated by 3 lecturers:

Weishun Xu- Zhejiang University, Matt Wallwork- University of Nottingham Ningbo China and Mia A. Tedjosaputro- Ningbo University.

Computationally designed by ZHU team and crafted manually by the keen makers. We are framing the research questions on potentials of mixed reality in architecture to aid design and construction processes. Derived from the observations of two bamboo pods construction (for first pod, click here), the aim is to contribute on the area of computational bamboo architecture.

Photographs courtesy of Sun Xintian, Yang Ruitong and myself.